Pallet Repair

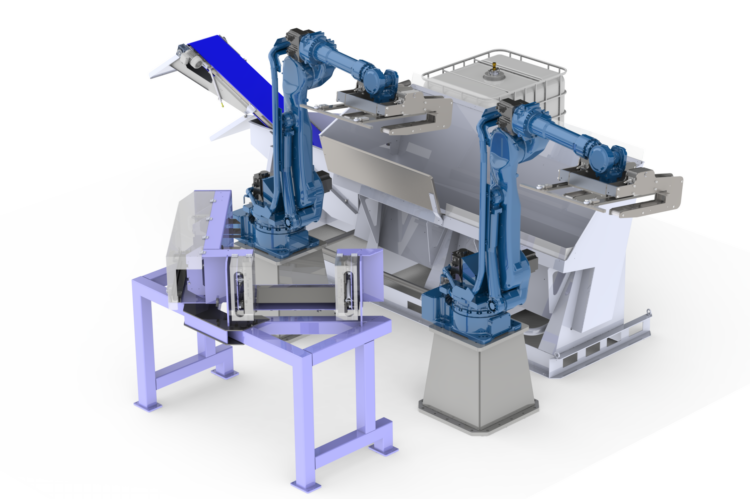

Automated Pallet Repair – A Sustainable Solution

At Prepac, we believe in repairing instead of replacing. Choosing pallet repair over replacement is a smart and sustainable way to manage resources, reduce waste, and lower operational costs. Our automated systems extend pallet lifespan and help reduce your company’s environmental footprint.

Investing in repair supports a circular economy where materials are reused, emissions are minimized, and sustainability becomes a core part of your logistics chain. It’s a solution that benefits both your business and the planet.

Pallet Dismantling

Ergonomically and long-lasting dismantling, is challenging for all pallet handling companies.

Pallet Auto Nailing

Automated nailing revolutionizes pallet repair by combining speed, precision, and cost-effectiveness. This advanced technology replaces labour-intensive, ergonomically challenging tasks with automation.

Stringer Machine

The Stringer Machine is a fully automated unit designed to efficiently insert missing stringer boards onto pallets and securely nail them in place for transport.

Ergonomics in Pallet Repair – Reducing Heavy Manual Labor

Traditional repair methods involve repetitive lifting, hammering, and prying—tasks that strain workers and increase injury risk. Just like our pallet collar automation, our systems are designed to minimize manual labor and improve workplace ergonomics.

By reducing ergonomic stress and common injuries, our machines help create a safer environment where employees can focus on more valuable tasks.

Key Benefits of Automated Pallet Repair Systems

Cost Savings

Automation significantly reduces the cost per repaired unit compared to manual work or purchasing new pallets—resulting in long-term financial gains.

Consistent Quality

Machines ensure each repair is completed to a consistent, high standard, boosting pallet reliability and minimizing damage-related shipping issues.

Increased Throughput

Automated systems increase repair capacity and help meet rising operational demands without large staff expansions. When combined with our automated palletizers, your process becomes even more streamlined.

Customizable Solutions

We design every system to fit your specific needs. Whether you need a basic setup or a fully integrated solution, our technology helps reduce manual handling across your logistics workflow.

Why Prepac is Your Pallet Repair Partner

Since 1987, Prepac has delivered flexible, robotic solutions for industrial automation. Whether you need to restore used pallets or manufacture new ones, our systems are designed to match your exact production goals.

With proven experience, reliable performance, and a commitment to sustainable manufacturing, Prepac is your trusted partner in advanced pallet repair solutions.

Contact us today to explore how automation can transform your operations.