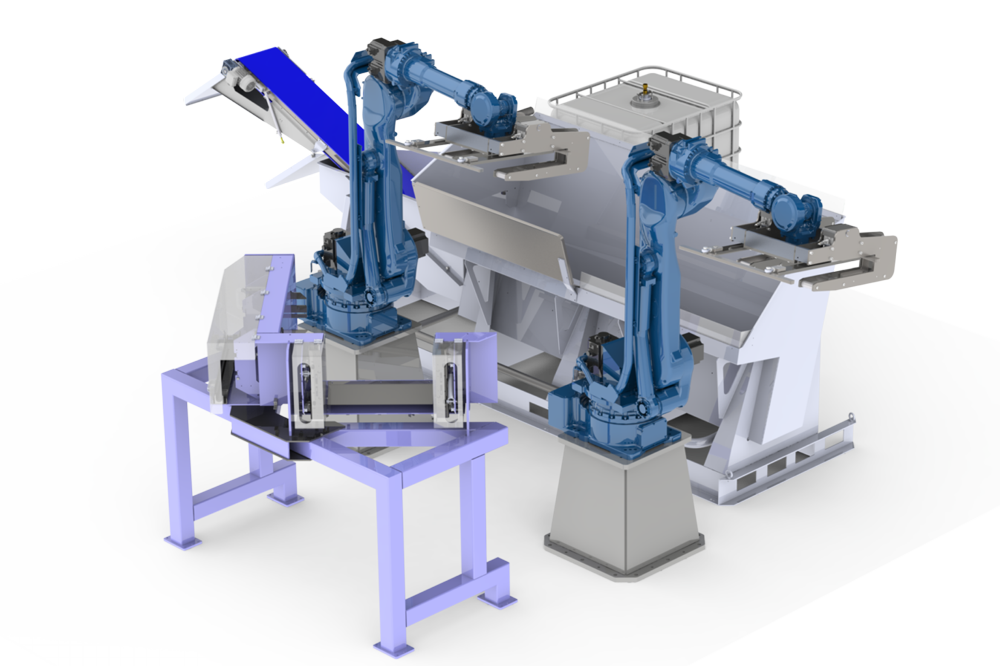

Pallet Dismantling

Efficient and sustainable pallet dismantling

Ergonomically and long-lasting dismantling, is challenging for all pallet handling companies.

Our pallet dismantling cell consists of two machines, with one or two robots feeding them. Using our custom-built grippers and depending on setup, the cell can handle two or three pallet size variations and pallet capacity, making it highly adaptable to your specific operational needs. A measuring unit checks the thickness and spacing of the boards on the pallet to determine if and where the pallet needs to be cut to remove the damaged boards. The pallets are then fed into a saw, with the robot still holding onto the pallet and guiding it through the cutting process to precisely remove the damaged boards and/or blocks, allowing the pallet to be re-nailed preferably in our Auto nailing cell and reused. The scrap parts are conveyed away from the dismantling unit to ensure smooth operation and minimize downtime.

- Seamless integration

- Improved safety

- Pallet processing capacity 60-120 pallets per hour (PPH)